News

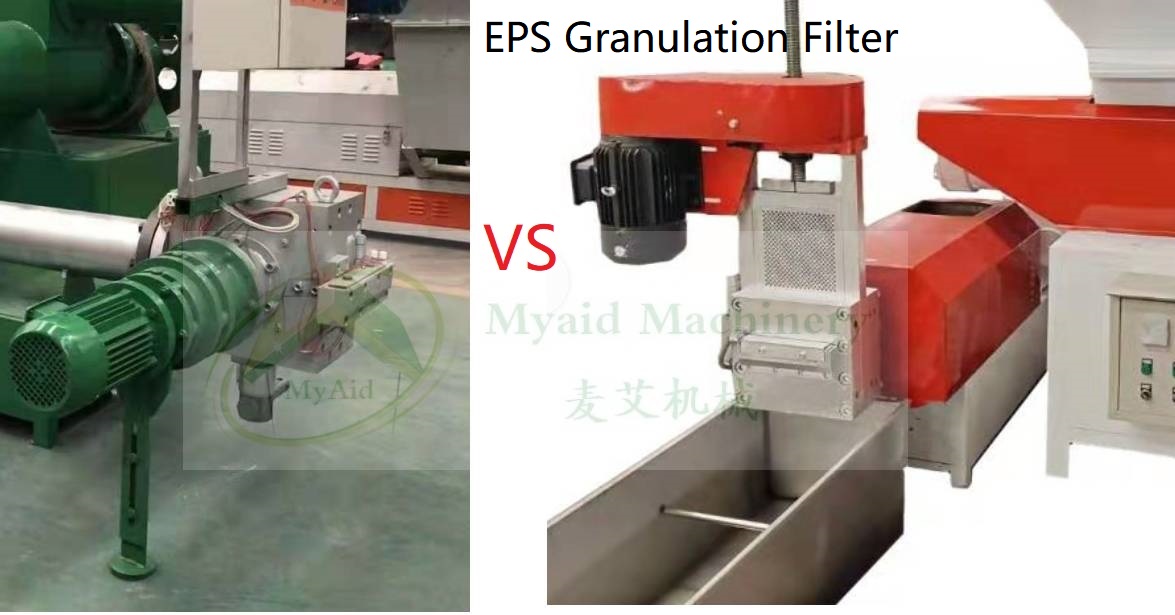

Comparison of EPS granulation filter with screen and without screen

Disadvantage of EPS granulation filter with screen

The EPS granulation filter is traditional unit which can trace back over 20 years ago.The screen at filter needs to be replaced every 5-15 minutes due to the impurities are filled and blocked at the screen mesh holes.The replacement work need extra care and time from labor,so it is a waste of labor.Workers will feel tired of it.The whole granulation line needs about 2-3 labours.Most of recycling factories in the market are using this type of filter at their EPS granulation machine.

One thing needs to notice that some small factories for EPS granulation machine make bad quality machine.Their machine needs to replace screen after you turn off machine.

Another drawback from the filter with screen is that it wastes extra EPS materials during replacement.About 10% strand is waste.

Advantage of EPS granulation filter without screen

The workforce is reduced a lot after using granulation filter without screen.2 worker can be enough for the whole line.And their work strength is not much.

No extra EPS materials to be waste and capacity for the whole line increases up 10%.

No need to buy new screen.The screen itself is also a cost.

Conclusion

So,we can conclude that the EPS granulation filter is new technology and workers like it more.Cause it saves time and workforce during production.It also saves cost of screen.The EPS materials also can be saved too.

Product Category

Hot Items

Foam Dedusting Crusher - EPS De dust machine

Foam Dedusting Crusher - EPS De dust machine New EPS Styrofoam Densifier Melts without Pre-heating Time

New EPS Styrofoam Densifier Melts without Pre-heating Time EPS pelletizing machine - strand die works without filtering screen

EPS pelletizing machine - strand die works without filtering screen CNC hot wire 2D cutting machine with wire oscillation

CNC hot wire 2D cutting machine with wire oscillation hot wire CNC foam cutting machine with turntable for 2D/3D/4D models

hot wire CNC foam cutting machine with turntable for 2D/3D/4D models full automatic and continuous eps cutting line

full automatic and continuous eps cutting line

Live Help

0086 13833131292

0086 13833131292 0086 311 86558425

0086 311 86558425

English

English Espanol

Espanol Arabic

Arabic