News

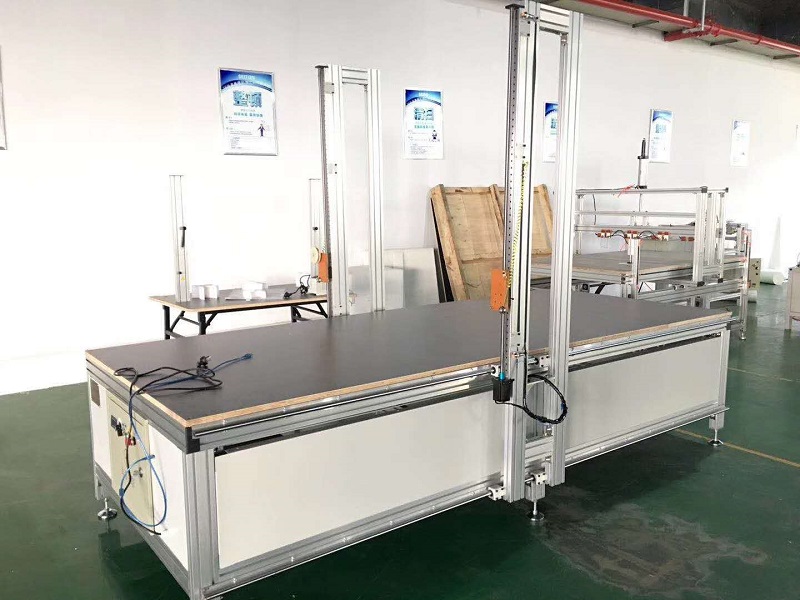

what is hot wire EPS foam cutting machine?

A hot wire EPS foam cutting machine is a type of machine that uses a heated/hot wire to cut EPS foam. The wire is typically made of nichrome, which is a type of metal that has a high melting point. The wire is heated to a high temperature, and then it is passed through the foam. The heat from the wire melts the foam, and the wire cuts through the foam as it passes through.

Hot wire EPS foam cutting machines are used for a variety of applications, including:

- Creating models and prototypes

- Making signs and displays

- Building insulation

- Making packaging

Hot wire EPS foam cutting machines are a versatile tool that can be used for a variety of purposes. They are relatively easy to use, and they can produce accurate and precise cuts.

Here are some of the advantages of using a hot wire EPS foam cutting machine:

- They are relatively inexpensive to purchase and operate.

- They are easy to use and can be operated by a single person.

- They can produce accurate and precise cuts.

- They can be used to cut a variety of different types of EPS foam.

Here are some of the disadvantages of using a hot wire EPS foam cutting machine:

- They can be slow to cut large pieces of foam.

- They can produce fumes that can be harmful to your health.

- They can be difficult to clean.

Overall, hot wire EPS foam cutting machine is a versatile and affordable tool that can be used for a variety of applications. If you are looking for a way to cut EPS foam, a hot wire EPS foam cutting machine is a good option to consider.

Product Category

Hot Items

Foam Dedusting Crusher - EPS De dust machine

Foam Dedusting Crusher - EPS De dust machine New EPS Styrofoam Densifier Melts without Pre-heating Time

New EPS Styrofoam Densifier Melts without Pre-heating Time EPS pelletizing machine - strand die works without filtering screen

EPS pelletizing machine - strand die works without filtering screen CNC hot wire 2D cutting machine with wire oscillation

CNC hot wire 2D cutting machine with wire oscillation hot wire CNC foam cutting machine with turntable for 2D/3D/4D models

hot wire CNC foam cutting machine with turntable for 2D/3D/4D models full automatic and continuous eps cutting line

full automatic and continuous eps cutting line

Live Help

0086 13833131292

0086 13833131292 0086 311 86558425

0086 311 86558425

English

English Espanol

Espanol Arabic

Arabic