News

How to make EPS blocks from EPS trimming materials?

During the EPS insulation block making process,workers always trim the block during cutting,these trimming will be recyclable to make insulation block again.

How to do it?

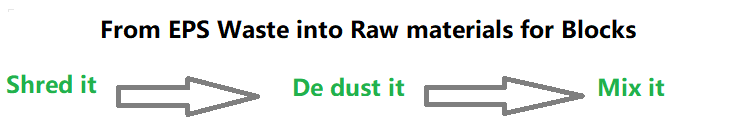

Our automatic EPS cutting line can trim the EPS block autocratically,the trimming will be automatically shred by the conveying shredder down the cutting line.After it,the shredded scraps will be de-dusted and then conveyed to silo on the EPS mixer which will mix the recycled beads with pre expanded beads.These materials will be conveyed to silo on the block molding machine.This is the whole process.

EPS manufacturing process:

EPS Raw beads are pre expanded using steam from boiler, creating pre puff beads, which are then cured in large silo before being conveyed to the mold. Once in the mold, the pre puff beads are again steamed to form a block in the block mold machine that is anywhere from 2m to 8m. The blocks are then placed on the storage floor to age for the appropriate length of time before being cut into various shapes and sizes by EPS cutting machine. EPS Blocks are produced in several densities to meet specific project needs.

Product Category

Hot Items

Foam Dedusting Crusher - EPS De dust machine

Foam Dedusting Crusher - EPS De dust machine New EPS Styrofoam Densifier Melts without Pre-heating Time

New EPS Styrofoam Densifier Melts without Pre-heating Time EPS pelletizing machine - strand die works without filtering screen

EPS pelletizing machine - strand die works without filtering screen CNC hot wire 2D cutting machine with wire oscillation

CNC hot wire 2D cutting machine with wire oscillation hot wire CNC foam cutting machine with turntable for 2D/3D/4D models

hot wire CNC foam cutting machine with turntable for 2D/3D/4D models full automatic and continuous eps cutting line

full automatic and continuous eps cutting line

Live Help

0086 13833131292

0086 13833131292 0086 311 86558425

0086 311 86558425

English

English Espanol

Espanol Arabic

Arabic