Home ›Products › Foam Recycling Machine

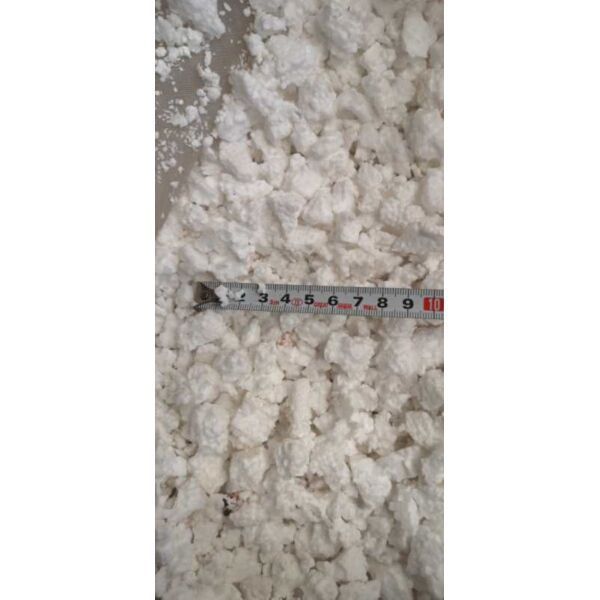

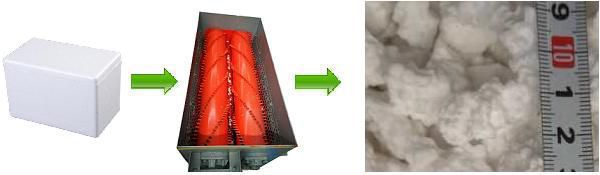

The design purpose of EPS grinder is to grind big EPS foam waste into different size of small balls/beads/granules etc as your demand.You can get recycled eps balls with size of 1cm,2cm,3cm.we can design and customize the machine with your demand.

Specification

|

Model no.

|

SW1000

|

SW1200

|

SW1500

|

|

Inlet size

|

1000*800mm

|

1200*800mm

|

1500*800mm

|

|

Motorreducer power

|

3kw

|

5.5kw

|

7.5kw

|

|

Rotating shaft qty

|

2 pcs

|

2 pcs

|

2 pcs

|

|

Blower power

|

3kw

|

5.5kw

|

5.5kw

|

|

Output granules dia.

|

20mm

|

20mm

|

20mm

|

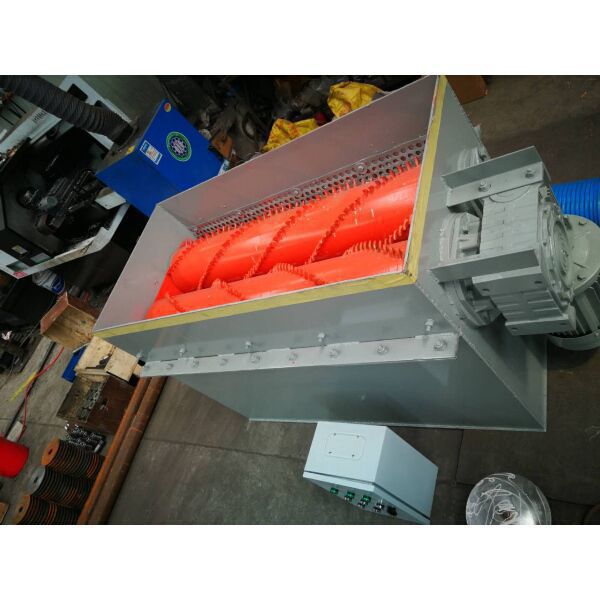

The dual shaft EPS shredder is fully designed for recycling EPS styrofoam waste with coordination of smaller diameter output and better capacity of eps shredding.The polystyrene waste will be reduced to nuggets which are to be sold or used again in package or board insulation line.The waste volume will be largely reduced by our eps recycling machine.

The EPS shredder is designed with two rotating shafts on top and one fixed shaft thing below the two shafts.The polystyrene waste will be rotating until it shred to size similiar to holes of screening mesh.

Cause the inlet is big size,so,it works well with different size of eps styrofoam waste like foam package,foam block,eps trimmings etc.

It has below features:

1) Two rotating shafts and one fixed shaft.It is twin shaft eps shredder.

2) The blade layout on the shaft are redesigned for recycling the size of eps styrofoam.

3) The size of blade on the shaft of two shaft eps shredder is just good for working with the machine.

4) Big power of motor reducer and blower on the eps shredding machine.

5) The Machine height is good with the big power of machine,no materials can escape from inlet.

Question and Answer

Q: What is the difference of this EPS shredder and other shredders?

A: The blades on the shafts are much smaller as teeth size.

Q: What will be the materials output size ?

A: 20mm - 30mm diameter.

Q: What is its materials application?

A: They can be used as EPS fillings.It is an alternative to traditional fill materials, taking advantage of its combined load-bearing capability and lightweight attributes.

Youtube video

Related Items

Product Category

Hot Items

Foam Dedusting Crusher - EPS De dust machine

Foam Dedusting Crusher - EPS De dust machine New EPS Styrofoam Densifier Melts without Pre-heating Time

New EPS Styrofoam Densifier Melts without Pre-heating Time EPS pelletizing machine - strand die works without filtering screen

EPS pelletizing machine - strand die works without filtering screen CNC hot wire 2D cutting machine with wire oscillation

CNC hot wire 2D cutting machine with wire oscillation hot wire CNC foam cutting machine with turntable for 2D/3D/4D models

hot wire CNC foam cutting machine with turntable for 2D/3D/4D models full automatic and continuous eps cutting line

full automatic and continuous eps cutting line

Live Help

0086 13833131292

0086 13833131292 0086 311 86558425

0086 311 86558425

English

English Espanol

Espanol Arabic

Arabic