News

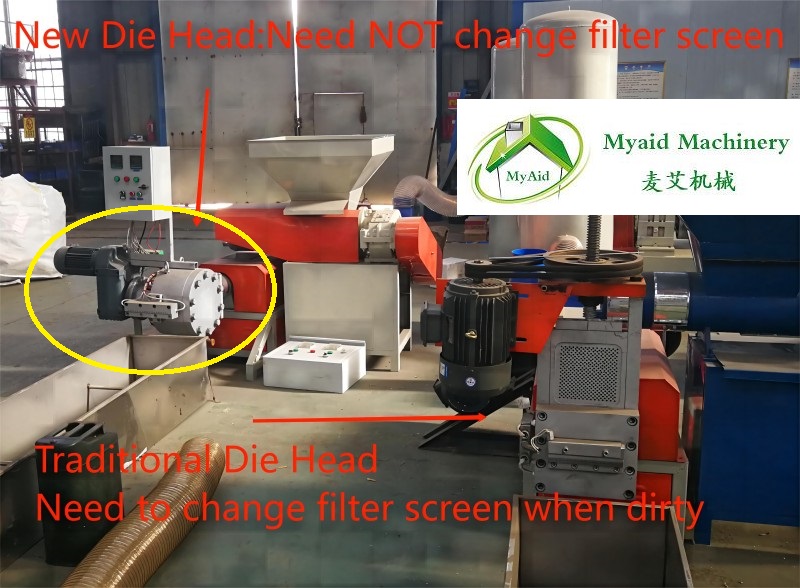

Filter die head without screen replacement when granulating

Advantages of die head without screen replacement for EPS granulation machine

1. Effectively improve production efficiency: Compared with the traditional mesh-based filter die, the mesh-less filter die does not need to frequently replace the filter during the production process, so it can greatly reduce downtime and improve production efficiency.

2. Easy maintenance: The die head without screen replacement has a simple structure and is easy to clean, which can greatly reduce equipment maintenance costs.

3. Improve product quality: The die head without screen replacement avoids the influence of filter clogging factors and can reduce the wear and pollution of fine particles, thereby improving product quality.

4. Reduce energy consumption: Since the meshless filter die itself has small resistance and the filter is smoother, energy consumption can be reduced.

5. The product is more in line with environmental protection requirements: Because the meshless filter die can be pollution-free and residue-free, it can better meet environmental protection requirements.

Disadvantages of the meshless filter die

1. The initial cost of the EPS granulation machine is high: The cost of EPS granulation machine using a die head without screen replacement is higher than that of traditional equipment because it uses more advanced manufacturing technology and requires processing of a more difficult filter outlet hole. It will also increase manufacturing difficulty and cost.

2. Complex maintenance: Because the structure, material and technical requirements of the meshless filter die are relatively high, maintenance is relatively difficult and needs to be handled by professional technicians.

Operation Precautions

1). Because the meshless filter die uses gravity to produce the filter effect, the filter outlet must have an appropriate tilt angle during installation, so as to ensure the production quality of the product and the normal operation of the equipment.

2). Do not granulate raw materials that contain unnecessary materials or a large amount of metal impurities, otherwise the die head will be damaged.

3). For EPS granulation machine that need to work for a long time, the use of the die head should be checked regularly and cleaned to ensure its normal operation.

4). In addition, attention should be paid to the sealing of the die head during use. If the sealing is poor, it will lead to cross-contamination between coarse and fine particles, thus affecting the quality of the final product.

In short, the meshless filter die is a new technology that has many advantages over the mesh-based filter die for EPS granulation machine.

Next: what is EPS loose foam ?

Product Category

Hot Items

Foam Dedusting Crusher - EPS De dust machine

Foam Dedusting Crusher - EPS De dust machine New EPS Styrofoam Densifier Melts without Pre-heating Time

New EPS Styrofoam Densifier Melts without Pre-heating Time EPS pelletizing machine - strand die works without filtering screen

EPS pelletizing machine - strand die works without filtering screen CNC hot wire 2D cutting machine with wire oscillation

CNC hot wire 2D cutting machine with wire oscillation hot wire CNC foam cutting machine with turntable for 2D/3D/4D models

hot wire CNC foam cutting machine with turntable for 2D/3D/4D models full automatic and continuous eps cutting line

full automatic and continuous eps cutting line

Live Help

0086 13833131292

0086 13833131292 0086 311 86558425

0086 311 86558425

English

English Espanol

Espanol Arabic

Arabic