News

Different designs of EPS Thermocol Scooping Machine

An EPS scooping machine is a machine that is used to cut or shape EPS (expanded polystyrene) foam into desired shapes for thermocol packaging. It is a versatile machine that can be used to create a variety of shapes, including boxes, trays, inserts, and even custom-designed pieces.

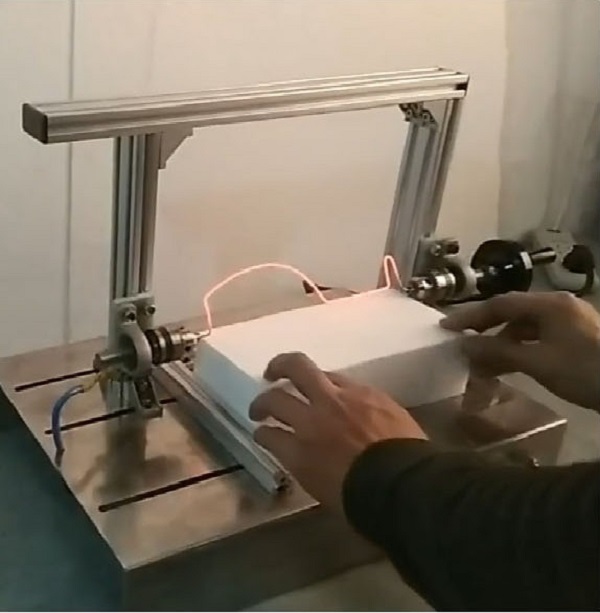

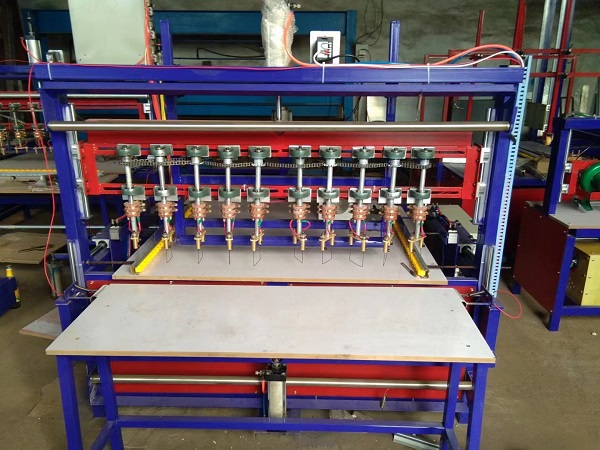

The machine consists of a heated blade that is used to melt the EPS foam. The molten foam is then forced through a die, which determines the shape of the finished product. The machine can be operated manually or automatically, and it can be used to produce a variety of shapes and sizes.

If you are looking for a way to improve cutting the efficiency and accuracy of your thermocol packaging, then an EPS scooping machine is a good option to consider.

There are several main types of EPS scooping machines for thermocol packaging: manual and automatic.

Manual EPS scooping machines are the simplest type of machine. They are operated by a human operator who manually guides the blade through the EPS foam. These machines are typically less expensive than automatic machines, but they are also less productive.

Automatic EPS scooping machines are more complex than manual machines. They are equipped with a robotic arm that automatically guides the blade through the EPS foam. These machines are more expensive than manual machines, but they are also more productive.

In addition to the two main types of EPS scooping machines, there are also a few other designs that are available. These include:

CNC EPS scooping machines:These machines are computer-controlled, which allows for even greater precision and accuracy.

The best design for an EPS scooping machine for thermocol packaging will depend on the specific needs of your business. Consider the volume of production, the complexity of the shapes that you need to cut, and your budget when making your decision.

Once you have considered these factors, you can start to compare different machines and find the one that is right for you.

EPS scooping machines are used by a variety of industries, including the packaging, electronics, and automotive industries. They are also used by businesses that need to create custom-designed thermocol packaging for their products.

Here are some of the benefits of using an EPS scooping machine for thermocol packaging:

* Increased productivity: EPS scooping machines can help to increase productivity by automating the process of cutting and shaping EPS foam.

* Improved accuracy: EPS scooping machines can help to improve the accuracy of the finished product by ensuring that all pieces are cut to the same size and shape.

* Reduced waste: EPS scooping machines can help to reduce waste by minimizing the amount of EPS foam that is wasted during the cutting process.

* Increased flexibility: EPS scooping machines can be used to create a variety of shapes and sizes, making them a versatile tool for thermocol packaging.

Product Category

Hot Items

Foam Dedusting Crusher - EPS De dust machine

Foam Dedusting Crusher - EPS De dust machine New EPS Styrofoam Densifier Melts without Pre-heating Time

New EPS Styrofoam Densifier Melts without Pre-heating Time EPS pelletizing machine - strand die works without filtering screen

EPS pelletizing machine - strand die works without filtering screen CNC hot wire 2D cutting machine with wire oscillation

CNC hot wire 2D cutting machine with wire oscillation hot wire CNC foam cutting machine with turntable for 2D/3D/4D models

hot wire CNC foam cutting machine with turntable for 2D/3D/4D models full automatic and continuous eps cutting line

full automatic and continuous eps cutting line

Live Help

0086 13833131292

0086 13833131292 0086 311 86558425

0086 311 86558425

English

English Espanol

Espanol Arabic

Arabic