News

EPS block making factory display

Company overview

Our EPS block making factory make eps insulation sheets with annual capacity for 800 ton with 50000 m³.factory covers land of 5000㎡.The eps insulation sheets can be good for insulation purpose which enjoys good market.

Project overview

People requires high quality exterior wall materials as the development of modern industry and the awareness of environment.The EPS sandwich sheets can be better insulation effects,reduce the temperature changes,reduce the warmth of building,working time of air conditioning,the energy consumption will be reduced and residential comfortness are improved.The thickness of eps sandwich sheets are largely reduced compared with other industrial wall materials,the wall weight and construction time and building materials are greatly reduced.

Color-steel eps sandwich sheets are a new type of energy-saving decorative metal sheet for construction, which is made of double-layer hot-dip galvanized color-coated thin steel plate and polystyrene insulation board. Polystyrene insulation sheet is one of the important raw materials for the production of color steel insulation sandwich sheets. The current market demand exceeds supply.So,our factory takes the opportunity and build up our factory with annual capacity of 800 tons.

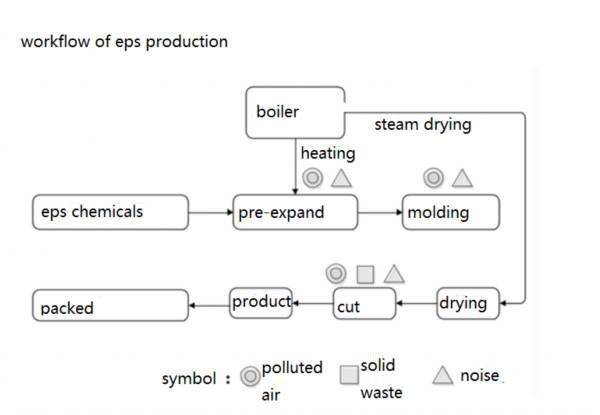

Workflow of EPS sheets making

The eps chemicals will be conveyed into EPS pre-expander and the steam will heat and make pre-expanding at 120℃,no need of foaming agent,the expanded beads will be conveyed to silo and block molding machine for making block which will be conveyed to drying room and cut by eps cutting machine.The sheets will be stored after test.The cut-off will be recycled.

Raw materials consumption

|

Raw materials name

|

Volume/year

|

unit

|

|

EPS chemicals

|

300

|

ton

|

|

Natural gas

|

60000

|

m³

|

Making Machines list

|

Name

|

Model no.

|

qty

|

|

Batch eps pre-expander

|

PSP140

|

2

|

|

EPS block molding machine

|

PSB-Q600

|

1

|

|

EPS cutting machine

|

PSQ300-800

|

4

|

|

Steam boiler

|

2-1.25.a2-00

|

1

|

|

pump

|

|

4

|

Environmental waste

Waste water

During the operation period of the project, the main drainage is the waste water from washing and toilet flushing of employees. The project has a capacity of 13 people. The domestic sewage generated by the project enters the septic tank first, and the sanitation department that has signed an agreement regularly cleans it and does not discharge it.

The waste gas produced by the project is discharged through the 15-meter-high chimney after being treated by the low-temperature plasma purification device, and the dust generated during the cutting process is processed by the bag filter and discharged through the 15-meter-high chimney.

Wasted air

The noise sources during the operation period of this project are mainly operating noise of foaming machines, panel machines, cutting machines, pumps, etc., and no production at night, so it will not cause trouble to the surrounding people.

Wasted noise

The source of solid waste in this project is the staff's office household waste and the waste gas packaging after unsealing the raw material woven bag. Collected and processed by the sanitation department (see Annex 7 for details). The waste packaging materials are collected by the construction unit and sold to the waste collection station, so that they will not cause pollution to the surrounding environment.

Solid waste

Enterprises operate in a law-abiding and honest manner, in accordance with the relevant provisions of the State Council’s "Regulations on the Collection and Use of Pollutant Discharge Fees", to declare and register pollutant discharge in accordance with the law, and to pay pollutant discharge fees in full in accordance with the law.

Product Category

Hot Items

Foam Dedusting Crusher - EPS De dust machine

Foam Dedusting Crusher - EPS De dust machine New EPS Styrofoam Densifier Melts without Pre-heating Time

New EPS Styrofoam Densifier Melts without Pre-heating Time EPS pelletizing machine - strand die works without filtering screen

EPS pelletizing machine - strand die works without filtering screen CNC hot wire 2D cutting machine with wire oscillation

CNC hot wire 2D cutting machine with wire oscillation hot wire CNC foam cutting machine with turntable for 2D/3D/4D models

hot wire CNC foam cutting machine with turntable for 2D/3D/4D models full automatic and continuous eps cutting line

full automatic and continuous eps cutting line

Live Help

0086 13833131292

0086 13833131292 0086 311 86558425

0086 311 86558425

English

English Espanol

Espanol Arabic

Arabic