News

The design of PLC controlling program for EPS block molding machine

The advantage of PLC program to molding machine

The EPS block molding machine is key machine for factory making EPS sheets.It takes EPS as raw materials which are pre-expanded,dried and ripened in the making process,then the EPS block molding machine will feed the EPS beads into its mold,the steam will heat the beads which will be formed into a block after it is cooled and steam out.The block will be ejected out of mold by compressed air and a flexible bar.The whole process is under control by Delta .It is simple to operate and good efficiency.

It has three advantages compared with other machines in the market.

1) Monitoring the production process

It takes HMI which can multifunctional screen design and the production process can be easily seen on it.it shortens the production procedure and saves energy.The whole process can be dynamically displayed on the screen.

2) Setup and corrections of parameter

It can set up the parameter for each block and the setup can be changed as per actual requirement.

3) Friendly HMI

The performance of colorful screen and control box is stable,so the operation can be simple and it is not unfriendly like other molding machines in the market.

4) Flexible application

The I/O interface can be added,it can communicate at long distance,so you can manage your network as per your request.

The structure of PLC

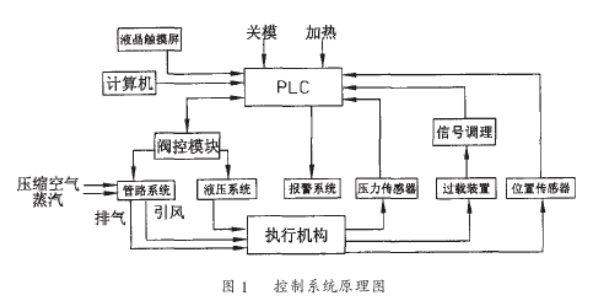

It consist of PLC ,touchable display terminal,steam tube ,compressed air tube ,hydraulic etc. Its principle is as above picture.

Software Design

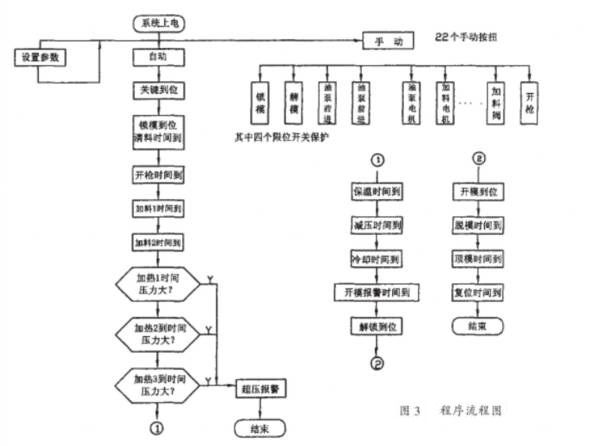

According to the requirement of EPS block molding machine,we draw the picture for production procedure after understand the chronological order and relations of all procedures. The PLC program input and output logical relations.The process dialog can be as below.The parameter setup,auto/manual directives are to be sent thru touchable screen to PLC program.

Application

The EPS block molding machine takes PLC and touchable image operation terminal,it is low energy consumption,low cost,high intelligent,so,it is suitable for EPS factories.These factories feedback that it is good design for their demand and it is simple to operate the machines with the PLC program.

Product Category

Hot Items

Foam Dedusting Crusher - EPS De dust machine

Foam Dedusting Crusher - EPS De dust machine New EPS Styrofoam Densifier Melts without Pre-heating Time

New EPS Styrofoam Densifier Melts without Pre-heating Time EPS pelletizing machine - strand die works without filtering screen

EPS pelletizing machine - strand die works without filtering screen CNC hot wire 2D cutting machine with wire oscillation

CNC hot wire 2D cutting machine with wire oscillation hot wire CNC foam cutting machine with turntable for 2D/3D/4D models

hot wire CNC foam cutting machine with turntable for 2D/3D/4D models full automatic and continuous eps cutting line

full automatic and continuous eps cutting line

Live Help

0086 13833131292

0086 13833131292 0086 311 86558425

0086 311 86558425

English

English Espanol

Espanol Arabic

Arabic