News

Production Process for eps insulation block

|

Eps block production process |

|

|

Process 1 |

Eps granules pre foam |

|

Process 2 |

Eps granules ripening |

|

Process 3 |

Eps block forming |

|

Process 4 |

Eps block drying |

|

Process 5 |

Eps block cutting and package |

Eps raw chemicals

Basis: eps + foaming agent + fire retardant agent

Diameter: screening in making decide the diameter,nothing to do with foam block density.

Foaming agent: isopentane,it takes 4-6% of total weight.It is liquid state in eps granules at normal state.

Fire retardant agent: hexabromocyclododecane,HBCD

Storing environment: away from heat,sunshine,fire,static and to be ventilated.

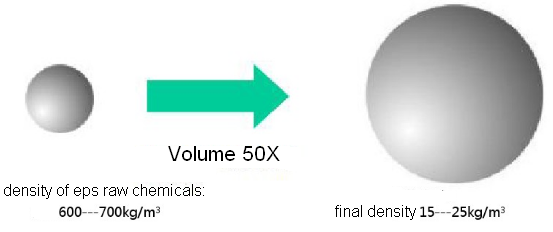

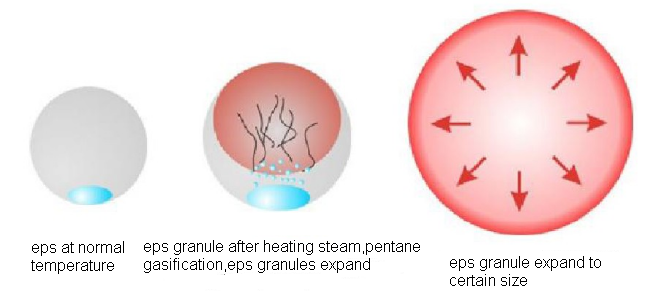

Principle of eps pre foam

`Heating on steam will make the eps granules grow big,bigger size will make different density.

`Different volume of eps granules are up to temperature and heating time.

`Bigger volume,smaller density,lower density of eps block.

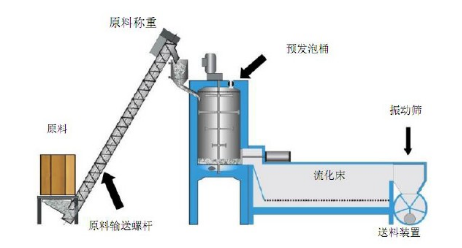

Continue eps pre foam machine

Feature

`eps granules feed into eps pre foam machine continually, foamed granules out from output.

Method to adjust the eps density

`adjust the steam volume supply

`adjust the supply of raw eps chemicals

`adjust the heighth of output device

Weekness

`foamed granules are not easy to control

`low productivity

`extra waste of energy

Batch eps pre foam machine

Feature

`eps granules are quantitatively feed into eps pre foam machine,foamed granules are out from machine to next cycle.

`adjust the steam pressure

`adjust the steam temperature

Advantage

`easy to control the eps density

`good productivity

`low energy consumption

Fluidize drying machine

Effect

Drying the surface of eps granules by blowing.

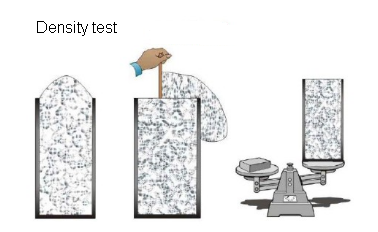

Density test

Tool: scale,barrel(1000L),template

Sample can be from machine output.

Test method:

Test barrel is full with eps granules,make it plane with template,test the weight.normally,density for eps foam is 0.5g/l heavier than block density

Process 2 Eps granules ripening

Principle for eps ripening

`The foaming agent and steam in the eps granules are cooled to be condensed,there will be vacuum in the granules.The process is in the eps silo system

.

Tip

The foamed granules are soft and can be knead to be flat by figures.

The ripened granules are elastic.

Process 3 eps block forming

Principle of eps block forming

`The eps granules feed into eps block forming machine,the granules will be expanded under the heating of steam.Within the forming shape of machine,the big eps block will be formed.

Process

`Eps granules feeding into eps block forming machine thru eps silo with the work of eps blower.

`steam will make the eps granules into block by controlling the timing.

` Temperature will be cooled down thru the vacuum system.

` Door open and formed block out and door close.

Advantage of eps vacuum system

`The extra steam and foaming agent will be out thru the vacuum system.The water content will be less and fire retardant performance will be better.

`The productivity will be stronger.

Process 4 Eps block drying

Why it needs to be dried in hot dring room?

`it need time to be dried and strong to be stable in size.

`The water content and foaming agent in eps block need to be volatilized.

` it needs to be cared in high temperature

`it needs to be cared in natural temperature.

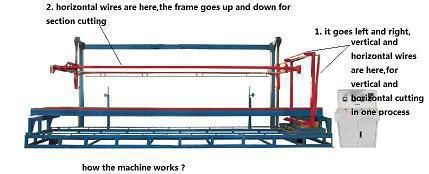

Process 5 Eps block cutting and packing

`Horizontal cutting wires

`Vertical cutting wires

`Down cutting wires

` automatic wires setting

` roll over feeding system

` eps shredder recycling system

` eps package machine

Myaid machinery supply eps insulation block machines,including prefoam machine,block molding machine,eps cutting machine and recycling machines from China.

Myaid Machinery

ADD: shijiazhuang city,050000,hebei province,China

Mobile&whatsapp: 0086 13833131292

Product Category

Hot Items

Foam Dedusting Crusher - EPS De dust machine

Foam Dedusting Crusher - EPS De dust machine New EPS Styrofoam Densifier Melts without Pre-heating Time

New EPS Styrofoam Densifier Melts without Pre-heating Time EPS pelletizing machine - strand die works without filtering screen

EPS pelletizing machine - strand die works without filtering screen CNC hot wire 2D cutting machine with wire oscillation

CNC hot wire 2D cutting machine with wire oscillation hot wire CNC foam cutting machine with turntable for 2D/3D/4D models

hot wire CNC foam cutting machine with turntable for 2D/3D/4D models full automatic and continuous eps cutting line

full automatic and continuous eps cutting line

Live Help

0086 13833131292

0086 13833131292 0086 311 86558425

0086 311 86558425

English

English Espanol

Espanol Arabic

Arabic