Home ›Products › EPS Foam Machine › Block Molding Machine

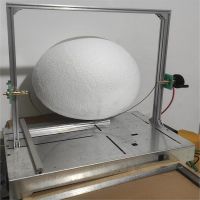

The EPS block machine is block height adjustable which is good for customers make different height EPS block.

We also invent block mould with one mould out of two EPS block like the picture shows.

Feature

1.EPS Block Molding Machine adopts PLC full computer touch screen displayer which can realize a full automatic cycle operation of mould opening, mould closing, material feeding, heating, heat preserving, vacuum cooling, demoulding and extruding-out of finished products.

2.The machine is welded by high-quality profile steel with aging heating treatment which can bring a high strength, non-deformation and high resistance to the expansive force from high-density products.

3. The machine is integrated with overseas advanced and special penetrating and heating techniques for shaping , and a high pressure suction fan for material feeding, cooling with a strong penetrability, favorable-adhesivity, low consumption of steam, high speed of shaping and low water content so as to ensure the uniformity of inside and outside of the product.

4. There are ventilation panel inside the block mold respectively at the 6 directions of its top, bottom, left, right, front and back, which will increase the airflow instantaneously and strengthen penetrating power. (We have got patent on a this technology)

2.The machine is welded by high-quality profile steel with aging heating treatment which can bring a high strength, non-deformation and high resistance to the expansive force from high-density products.

3. The machine is integrated with overseas advanced and special penetrating and heating techniques for shaping , and a high pressure suction fan for material feeding, cooling with a strong penetrability, favorable-adhesivity, low consumption of steam, high speed of shaping and low water content so as to ensure the uniformity of inside and outside of the product.

4. There are ventilation panel inside the block mold respectively at the 6 directions of its top, bottom, left, right, front and back, which will increase the airflow instantaneously and strengthen penetrating power. (We have got patent on a this technology)

√ Why you need molding machine with vacuum barrel ?

Its design can make heating process well-distributed,full beads expansion,little space among beads,low moisture for beads,sound panel shape,it full meets the requirement of the exterior wall panels.Whileas,the low quality molding machine can not control the density of panels,different density for different part of one panel,bog space among beads,not strongly combines,big moisture.

And The vaccum molding machine take 7-8 mins to make one panel,without vacum barrel,it takes 15 mins for one panel.

Its design can make heating process well-distributed,full beads expansion,little space among beads,low moisture for beads,sound panel shape,it full meets the requirement of the exterior wall panels.Whileas,the low quality molding machine can not control the density of panels,different density for different part of one panel,bog space among beads,not strongly combines,big moisture.

And The vaccum molding machine take 7-8 mins to make one panel,without vacum barrel,it takes 15 mins for one panel.

Youtube Video

Related Items

Product Category

Hot Items

Foam Dedusting Crusher - EPS De dust machine

Foam Dedusting Crusher - EPS De dust machine New EPS Styrofoam Densifier Melts without Pre-heating Time

New EPS Styrofoam Densifier Melts without Pre-heating Time EPS pelletizing machine - strand die works without filtering screen

EPS pelletizing machine - strand die works without filtering screen CNC hot wire 2D cutting machine with wire oscillation

CNC hot wire 2D cutting machine with wire oscillation hot wire CNC foam cutting machine with turntable for 2D/3D/4D models

hot wire CNC foam cutting machine with turntable for 2D/3D/4D models full automatic and continuous eps cutting line

full automatic and continuous eps cutting line

Live Help

0086 13833131292

0086 13833131292 0086 311 86558425

0086 311 86558425

English

English Espanol

Espanol Arabic

Arabic